EN Standard Prefabricated Steel Structure Office Building

High strength, light weight

Steel has excellent strength to weight ratio, making lightweight structures have high load-bearing capacity. This reduces the basic cost and allows for large-span design.

Excellent durability and disaster resistance

The anti-corrosion, seismic, and wind resistant designs comply with strict ASME standards, ensuring adaptability to extreme weather conditions, extending service life, and reducing maintenance costs.

Rapid modular structure

The combination of factory prefabrication and on-site welding can shorten construction time by more than 50%, reduce labor costs and on-site risks, and meet the needs of industrial construction.

Environmental protection and sustainable development

Steel is recyclable, generates minimal construction waste, and meets green building certification. Its lifecycle carbon footprint is lower than that of concrete structures.

Flexibility and cost-effectiveness

The adaptable spatial layout is easy to modify and upgrade. Although the initial cost may be slightly higher, shorter construction time and higher availability can bring long-term economic benefits.

Standardization and Quality Assurance

The ACRS specification ensures strict control over welding processes, materials, and inspections, keeping defect rates below the industry average and ensuring internationally recognized safety.

Multifunctional applications

Very suitable for industrial plants, commercial complexes, bridges, and special environments that require heavy loads or high temperature resistance.

Introduce

The EN standard production process typically includes the following key steps:

Requirement analysis: Clarify product requirements, including functionality, performance, and quality standards, to ensure clear production goals.

Design and development: Design products according to requirements, including technical drawings, material selection, and process planning, to ensure compliance with EN standards.

Raw material procurement: Procure raw materials that meet EN standards and conduct strict quality inspections to ensure compliance.

Manufacturing: Process, assemble, and test according to design specifications to ensure that every step meets EN standard production requirements.

Quality control: Conduct multi-stage inspections during the production process, including first article inspection, process inspection, and final inspection, to ensure that the product meets EN standards.

Testing and Validation: Conduct performance testing, safety testing, and other validations on the finished product to ensure compliance with all EN standard technical requirements.

Packaging and labeling: Pack products according to EN standards and correctly label product information and safety warnings to ensure compliance.

Final inspection and certification: The final inspection is conducted by a third-party organization and EN certification is applied for if necessary to ensure market compliance.

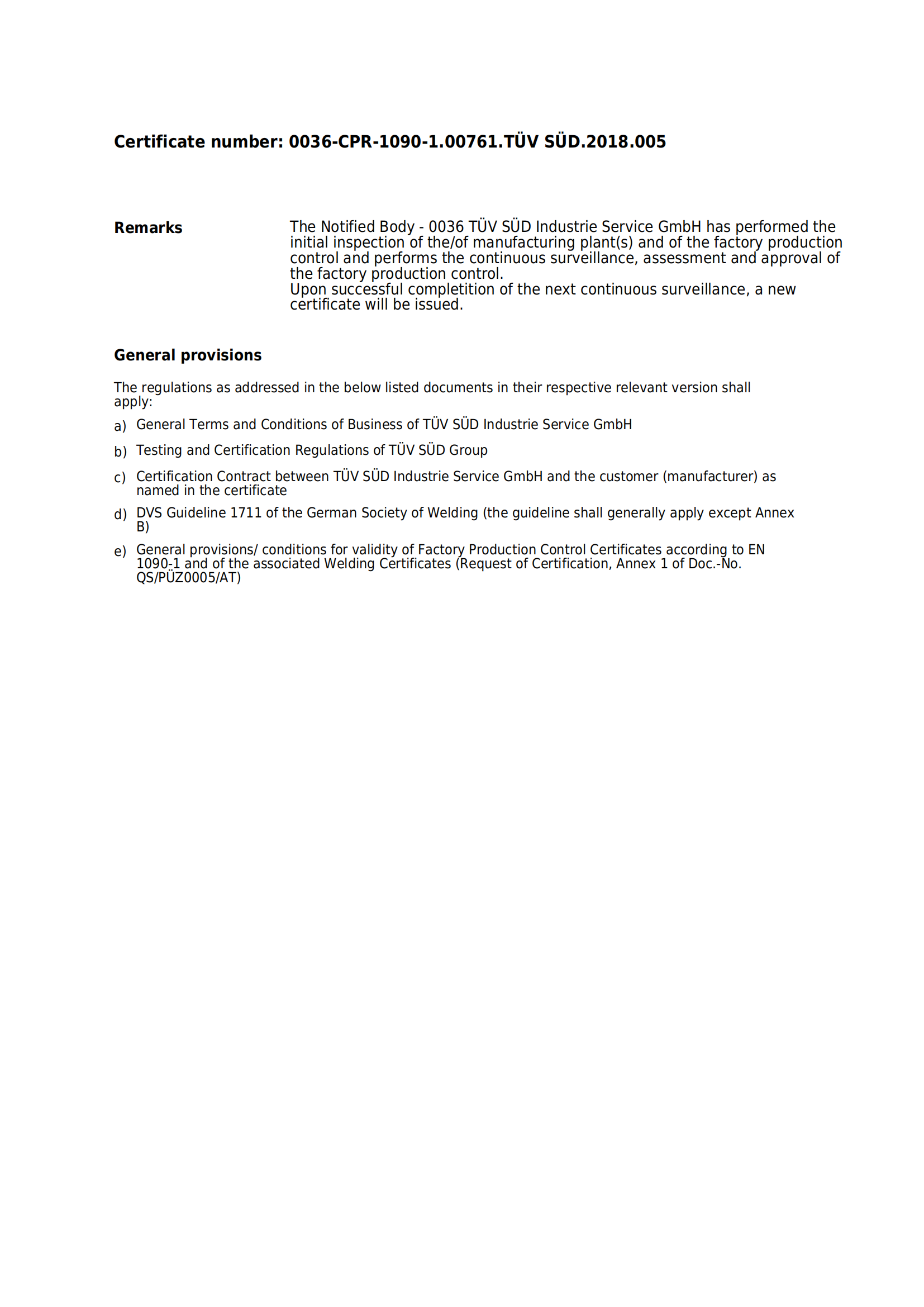

Standard Certificate

Guoshun Group has complete qualifications and adheres to the development philosophy of "providing comprehensive services for industrial environmental protection and energy conservation, and making customers more satisfied". Committed to creating comfortable spaces and improving the ecological environment. With the cooperation concept of not saying "no" to customers, we provide high-quality services to thousands of high-quality customers at home and abroad, and jointly create a beautiful tomorrow of innovation and renewal!

Submitted successfully

We will contact you as soon as possible